Eliminating Tooling Costs with Additive Manufacturing

In today’s competitive market, innovative product development is crucial for businesses to thrive and grow. However, traditional manufacturing processes often come with significant up-front tooling costs, making it a daunting prospect for many companies, particularly startups and small businesses. These costs can deter innovation and limit the potential for growth. Fortunately, there is a game-changer in the world of manufacturing – Additive Manufacturing (AM), also known as 3D printing. In this blog post, we will explore how AM addresses the issues of high tooling costs, and how it can revolutionize the product development process for businesses of all sizes.

Question 1: High Up-Front Tooling Costs

Traditional manufacturing processes like injection molding and CNC machining require expensive molds, dies, and tooling to bring a product from concept to reality. For many companies, especially those looking to develop new products or prototypes, these high tooling costs can be prohibitive. The investment in tooling alone can run into thousands or even millions of dollars, depending on the complexity of the design.

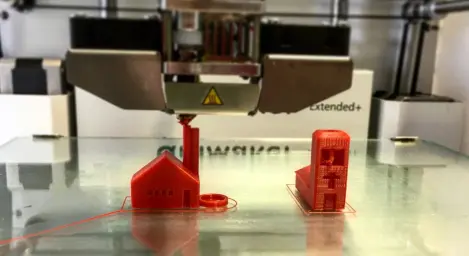

Additive Manufacturing provides a solution to this problem. Unlike traditional methods, 3D printing doesn’t require the creation of molds or tooling for production. Instead, it builds objects layer by layer directly from a digital design file. This means that companies can prototype and manufacture products without incurring exorbitant tooling expenses. By eliminating the need for tooling, businesses can quickly iterate and refine their designs at a fraction of the cost, making it easier to bring innovative products to market.

Question 2: Low to No Up-Front Tooling Investment

Imagine being able to launch a new product with minimal to no up-front tooling investment. What impact would this have on your business’s ability to grow and innovate? The answer is clear: it would be a game-changer. Additive Manufacturing makes this scenario a reality.

With 3D printing, companies can develop and test prototypes and even create end use parts without committing to expensive tooling upfront. This not only reduces financial risk but also accelerates the product development cycle. Businesses can bring new products to market faster, responding to changing market demands and consumer preferences with agility. With Additive Manufacturing, complexity is free, and products selling can be a variable cost only with no up-front fixed costs, reducing risk. Furthermore, products can easily be adjusted based on customer feedback, upending the traditional model of needing to sell thousands of units before recouping upfront costs and having very little ability to make changes after the fact. This speed and flexibility can be a significant competitive advantage, particularly in industries where innovation and time-to-market are critical.

Benefits of Additive Manufacturing

1. Cost-Efficiency: AM significantly reduces material waste, as it only uses the necessary amount of material to create the object. This leads to cost savings in terms of material usage and waste disposal.

2. Complexity and Customization: 3D printing allows for complex geometries and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. This capability is invaluable for creating highly customized or unique products.

3. On-Demand Production: With AM, companies can produce parts and products on-demand, eliminating the need for large inventories and reducing storage costs. This just-in-time production model can also minimize supply chain disruptions.

4. Reducing Lead Times: The elimination of tooling and the ability to quickly revise designs mean shorter lead times, reducing the time it takes to go from concept to market.

5. Low-mid Volume Production: 3D printing is ideal for low-mid volume production runs, making it cost-effective for small-batch manufacturing or personalized products.

Conclusion

In conclusion, Additive Manufacturing has the potential to revolutionize the manufacturing landscape by eliminating high up-front tooling costs and providing the flexibility to launch new products with minimal investment. Whether you’re a startup looking to bring innovative ideas to life or an established company seeking to streamline your product development process, 3D printing offers a range of benefits that can transform the way you do business. Embracing this technology can lead to cost savings, faster time-to-market, and greater competitiveness in an ever-evolving market. As the world of manufacturing continues to evolve, companies that harness the power of Additive Manufacturing are poised for success in the 21st century.