Unlocking Customization and Complex Parts with 3D Printing and Additive Manufacturing

In the world of manufacturing, one size rarely fits all. Many industries face the challenge of needing custom parts with intricate designs and complex geometries to meet their specific requirements. Traditional manufacturing methods often struggle to deliver the precision and design flexibility demanded by today’s innovative products. However, 3D printing and additive manufacturing have emerged as transformative solutions. In this blog post, we will explore how these cutting-edge technologies are addressing the need for customization and complex parts, while addressing the following questions:

1. Do you often need custom parts with intricate designs or complex geometries?

2. Have you found traditional manufacturing methods limiting in achieving the desired precision or design?

The Quest for Customization:

Customization has become a hallmark of modern manufacturing. From aerospace to healthcare to consumer goods, industries are constantly seeking unique solutions to address specific challenges. Traditional manufacturing often relies on mass production techniques, making customization a costly and time-consuming endeavor. This is where 3D printing and additive manufacturing shine:

1. **Tailored Designs**: With 3D printing, you can easily create tailored designs that precisely match your requirements. Whether it’s a unique medical implant or a specialized aerospace component, you have the freedom to design parts that fit your needs perfectly.

2. **On-Demand Production**: Additive manufacturing allows for on-demand production, meaning you can manufacture custom parts as needed, reducing the need for expensive inventory management and minimizing lead times.

3. **Patient-Specific Healthcare**: In the healthcare industry, 3D printing has enabled the creation of patient-specific implants and prosthetics, revolutionizing patient care by ensuring a perfect fit and function.

Complex Geometries Made Simple:

Complex geometries can be a headache for traditional manufacturing methods, often requiring multiple assembly steps and costly tooling. 3D printing, on the other hand, excels in creating intricate shapes and designs:

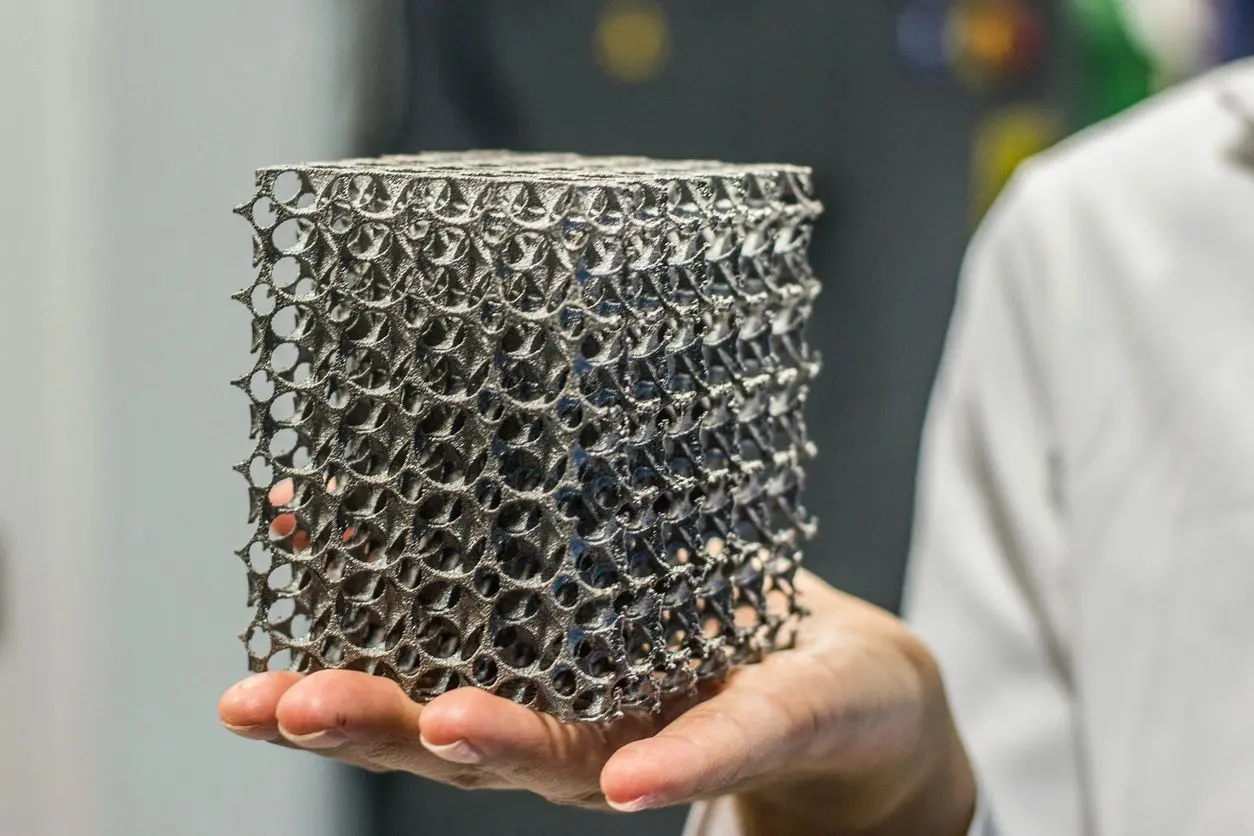

1. **Consolidated Parts**: Additive manufacturing enables the creation of complex parts as a single piece, reducing the need for assembly and minimizing potential points of failure.

2. **Lightweighting**: Achieving lightweight structures with traditional methods can be challenging. 3D printing allows you to optimize designs, reducing material usage while maintaining structural integrity.

3. **Innovative Design Freedom**: Designers and engineers can push boundaries with 3D printing, exploring innovative solutions that were previously impossible or cost-prohibitive.

Precision and Detail:

Precision is often non-negotiable, especially in industries where safety and performance are paramount. Traditional manufacturing may fall short in achieving the desired precision, but 3D printing offers:

1. **Microscopic Accuracy**: Some 3D printing technologies can achieve microscopic levels of accuracy, ensuring that even the most intricate and delicate parts meet precise specifications.

2. **Repeatability**: Additive manufacturing processes are highly repeatable, reducing variability and ensuring consistent quality across batches.

3. **Prototyping and Iteration**: Rapid prototyping with 3D printing allows for quick iterations and adjustments, ensuring that the final part meets the desired precision and design.

Conclusion:

In conclusion, 3D printing and additive manufacturing are revolutionizing the way industries approach customization and complex parts. Whether you need tailored designs, intricate geometries, or unrivaled precision, these technologies offer versatile solutions that traditional manufacturing methods often struggle to achieve. Embrace the power of 3D printing to unlock your business’s full potential, reduce production costs, and streamline your design processes. If you’ve been grappling with the limitations of traditional manufacturing, it’s time to explore the endless possibilities that additive manufacturing brings to the table. Embrace customization, conquer complexity, and redefine what’s possible in manufacturing.